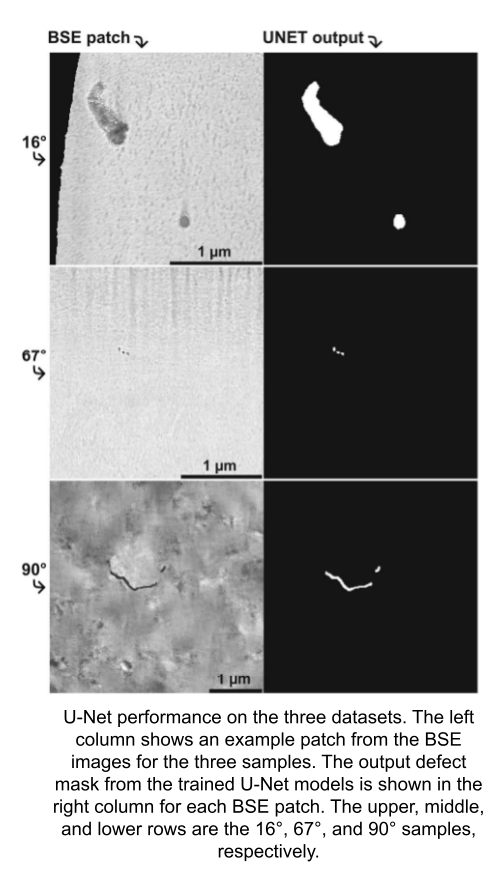

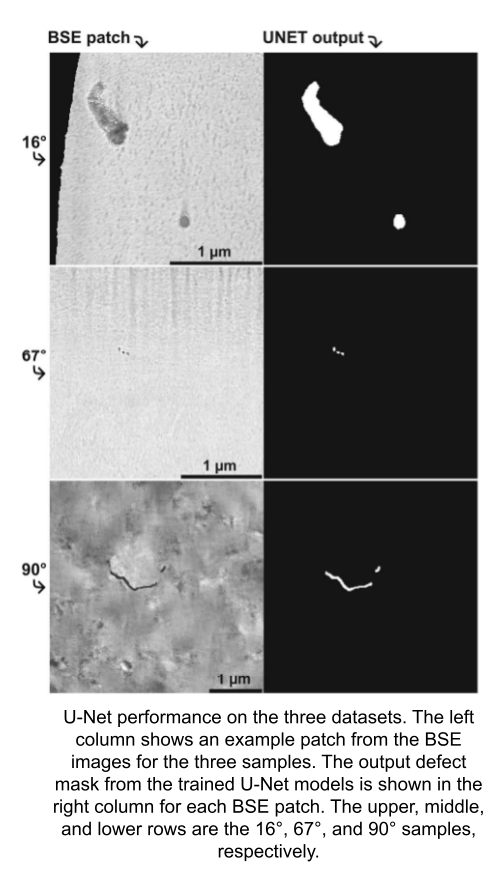

Laser powder bed fusion (LPBF) printing defects are investigated through multimodal 3D serial sectioning data on a model CoNi alloy. Defect segmentation across three different LPBF prints with different scan strategies, in which interlayer rotation and the presence of a contour scan is varied, reveal fully dense microstructures (>99.8% dense). Despite being in a density range commonly considered as fully dense material, these prints contain an array of small pores, lack-of-fusion defects, and cracks that can be highly anisotropic. Their size and number are compared to those found in conventional superalloy casting techniques (investment casting, single crystal Bridgeman casting). In the AM samples, most pores and cracks have a thickness on the order of 3–6 μm, beyond the resolution capabilities of most industrial non-destructive evaluation techniques. A comparison between 3D and 2D defects measurements is included, revealing significant variability between 2D measurements and the ground truth 3D data. A state-of-the-art machine learning framework, U-Net, is implemented for defect segmentation within three TriBeam tomography datasets containing backscattered electron images with variable contrast conditions. U-Net results indicate high-fidelity defect segmentation within all three datasets where recall and precision are >85%. The 3D reconstructions of the CoNi alloy samples provide insight into the defect content that can be expected from high-quality fully dense LPBF printed superalloy material.

.tiff image

.tiff image representing the output defect mask from the trained U-Net model.

Check out our paper here to learn more about the methods and the datasets we used to build the seam carving detector.

Click here for detailed instructions on how to run the module.